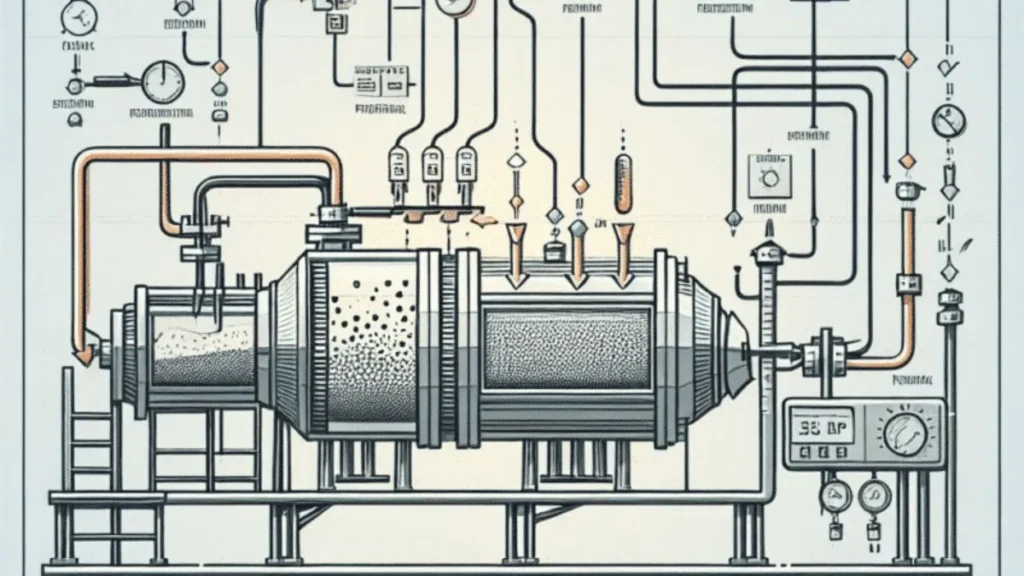

What is the Line Function of the Extruder Characteristics – This article explores the line characteristic of the extruder characteristics, particularly focusing at the vital functions of extrusion machinery used in production. The line feature of an extruder includes the transformation of raw substances—usually in pellet or powder shape—right into a continuous profile through heating, melting, and shaping these materials thru a die. The primary traits of the extruder, consisting of temperature manage, pressure build-up, and screw design, significantly affect the cloths flow and very last product best. Understanding these characteristics permits manufacturers to optimize the extrusion method, reaching desired consequences in productivity, efficiency, and product consistency.

Contents

- 1 Understanding Extruder Functionality

- 2 Key Characteristics of Extruders

- 3 Line Function: A Step-By-Step Process

- 4 Importance of Optimizing Extruder Characteristics

- 5 Conclusion

- 6 FAQs about What is the Line Function of the Extruder Characteristics

Understanding Extruder Functionality

The extruder serves as a pivotal component in numerous industries, particularly in plastic, rubber, and food production. By familiarizing yourself with its line function, you can efficaciously harness the equipment to gain premier production results. Below, we delve deeper into the unique traits and operational ideas of extruders, in the end highlighting how they contribute to the performance of manufacturing strategies.

Key Characteristics of Extruders

When analyzing the line function of extruders, numerous characteristics warrant interest. These tendencies now not best outline how the system operates however also have an effect on the excellent of the very last product. Here are some critical characteristics:

- Screw Design: The layout of the screw performs a important role within the extrusion procedure. It varies in geometry, pitch, and depth, affecting cloth flow, blending, and heating. A nicely-designed screw can decorate melting and homogeneity, important for generating excellent products.

- Temperature Control: Maintaining steady temperature at some stage in the extrusion system is vital. Effective temperature manipulate ensures the cloth achieves the precise viscosity, resulting in optimum glide via the die. Irregular heating can result in degradation and inconsistencies in the product.

- Pressure Management: The extruder should effectively generate and manage strain to facilitate cloth flow. Adequate stress helps in pushing the molten material thru the die but need to be controlled to keep away from immoderate pressure at the equipment.

- Cooling Systems: Post-extrusion cooling is important to solidify the fabric. This procedure impacts the form integrity and final residences of the extruded product.

Line Function: A Step-By-Step Process

To appreciate the road characteristic of the extruder, it is essential to understand the step-by way of-step process it undergoes when converting uncooked substances into finished products:

Feeding

The process starts with feeding uncooked substances into the extruder. This may be pellets, powders, or flakes. The feeding phase must ensure a regular feed price to maintain throughput and quality.

Melting

Once fed into the extruder, the cloth is subjected to warmth thru heated barrels. As the screw rotates, frictional warmness generated aids in melting the cloth, turning it into a viscous nation suitable for shaping.

Homogenization

During this phase, the melted fabric is blended thoroughly to make certain uniformity. Homogenization is critical for attaining constant product characteristics, especially in applications requiring particular residences.

Shaping

The homogenized material is then pressured thru a die, forming it into the desired shape. The die layout will dictate the scale and traits of the very last product.

Cooling and Cutting

After exiting the die, the extrudate is cooled to solidify its form. This segment can contain air cooling or water cooling, depending at the material and application. Finally, the product is reduce into workable lengths or processed similarly as required.

Importance of Optimizing Extruder Characteristics

Optimizing the extruder traits is essential for boosting manufacturing efficiency and product first-class. Here are some key benefits:

- Improved Quality: Well-optimized extruders yield merchandise with uniform properties, that is important in industries like meals, plastic, and rubber.

- Increased Efficiency: An green extruder minimizes downtime and maximizes output, which translates to reduced operational fees.

- Enhanced Flexibility: Understanding the road features allows manufacturers to evolve the technique for one-of-a-kind materials and programs seamlessly.

Conclusion

The line function of extruder traits is essential to recognize for producers aiming to optimize their production approaches. By focusing on key factors together with screw layout, temperature control, and pressure control, you may appreciably beautify product excellent and operational efficiency. Continuous improvements in extrusion era promise to propel the industry forward, making it important for experts to stay abreast of first-class practices and innovations.

FAQs about What is the Line Function of the Extruder Characteristics

What materials can be processed the usage of an extruder?

Extruders are designed to procedure a whole lot of substances, inclusive of thermoplastics, thermosetting plastics, elastomers, and food substances. The compatibility depends at the specific design and configuration of the extruder.

How does the choice of screw design impact the extrusion procedure?

The choice of screw layout is paramount since it impacts fabric drift, melting efficiency, and combining. Different programs may additionally require varying screw designs, together with unmarried or twin-screw extruders, to attain the desired product traits.

What are the environmental considerations while operating an extruder?

Environmental concerns include handling emissions, electricity intake, and waste substances. Implementing sustainable practices inclusive of the usage of recyclable substances and adopting electricity-green technology can mitigate environmental affects.

Also Check: What is the Major Product of the Following Reaction

Say Job City in Pakistan for today latest jobs opportunities in private and Govt departments. View all new Government careers collected from daily. sayjobcity.com